On-Demand CNC Machining

Precision, Customization, Rapid Turnaround.

Looking for precision CNC machining services for metal and plastic parts? Hardware Rapid delivers high-quality results from prototyping to low-volume production.

Your One-Stop Shop for Precision Machined Parts

Leveraging a complete fleet of machines—including lathes, mills, and turn-mill compound systems—XINGDA CNC delivers comprehensive solutions. Whether you need roughing or high-precision grinding, we ensure every complex part meets your exact specifications.

CNC Milling

The top choice for rapid prototyping and custom low-volume runs.

- Capabilities: 3, 4-Axis Machining

- Materials: Aluminum, Steel, PEEK & more

CNC Turning

Precision custom turning for shafts, pins, bushings, and cylindrical geometries.

- Capabilities: CNC Lathe & Turn-Mill

- Materials: Metals, Plastics, & Bar Stock

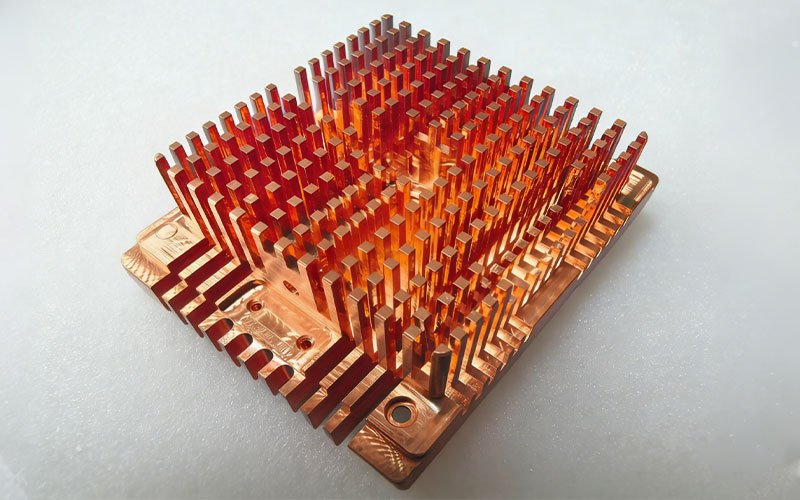

5-Axis CNC Milling

Fewer fixtures, higher precision. Engineered for high-accuracy custom parts.

- Features: Simultaneous 5-Axis

- Advantage: Tighter tolerances & superior surface finish

We have completed 10,000+ projects

Numbers speak louder than words. We have transformed over 10,000 digital designs into high-quality physical parts for engineers and businesses worldwide. Whether it’s a single prototype or a production run, we bring the same level of dedication and precision to project #1 as we did to project #10,000.

120k+

Number of Completed Parts

15+

Years Experience

20+

Seasoned Machinists

Rapid Prototyping

Whether you are testing for fit, form, or function, our precision machining ensures your prototypes meet strict tolerances and mechanical requirements. Iterate faster, validate designs with confidence.

Low-Volume Manufacturing

Need end-use parts but not ready for mass production? Skip the expensive molds and long lead times. Whether you need 10 or 1000 units, we deliver consistent, high-precision parts fully finished and ready for assembly.

CNC Machining Materials

Our facility works with a wide range of metals, plastics, and composites. Below is a list of the materials we frequently machine.

CNC Machining Finishes

Improve part performance and appearance. We offer a wide range of finishes to ensure wear resistance and corrosion protection. Explore our mechanical and chemical options below.

Bead Blasting

Powder Coating & Wet Painting

Metal Plating

Part Marking

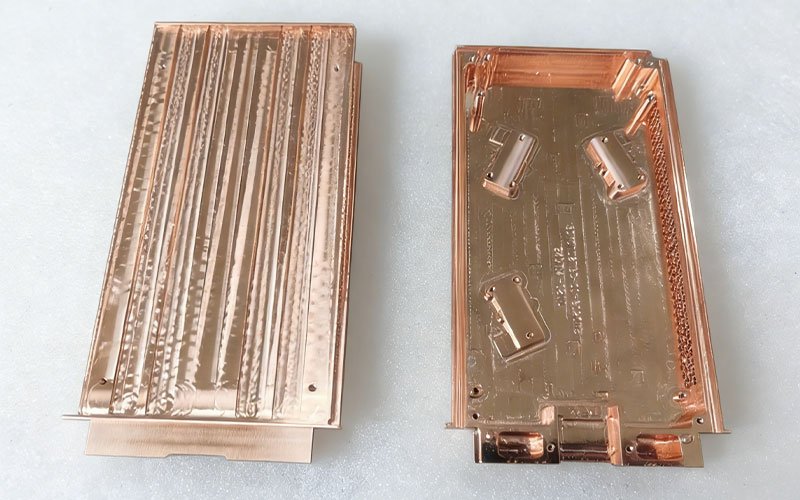

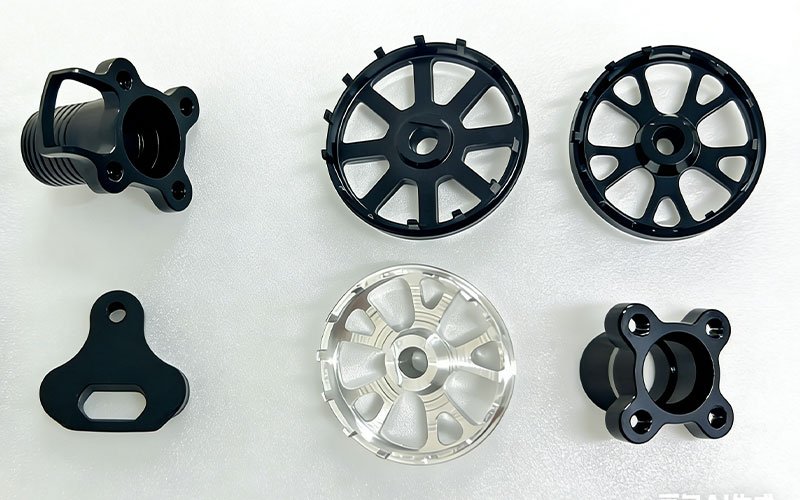

Our Portfolio

This portfolio shows some of our recent work — from one-off prototypes to low-volume production parts. We’ve done projects for aerospace, automotive, electronics and industrial fields, all made to meet exact client requirements and tight tolerances.

FAQs About CNC Machining Services